At Gemini Machining, we believe in offering our clients true value-added machining. That means an extra level of service with our precision machining, precision milling and precision turning work – a necessity in the highly competitive fields in which our customers operate.

We are different from most machining shops – even those that can match our precision milling and precision turning capabilities. How?

Client Service

Our business is predicated on thrilling clients, both with our work and our responsiveness. Everyone we contract with has access to everyone who works on their project – from team leaders and engineers to CNC operators, machinists and QC personnel. When you call Gemini, you always get a human being on the phone – never a phone tree or machine.

Gemini works with customers to facilitate cost effective, efficient ordering through blanket orders with customer-defined release dates. We also provide material certifications and C of C with orders at no additional charge.

Exacting Tolerances

Our precision machining projects almost always require a significant level of complexity – because the part is extremely difficult to manufacture, requires a very particular visual appearance or needs geometrical dimensioning or geometrical tolerancing.

Engineering Review

At Gemini, no precision machining, precision milling or precision turning project goes into production without first being approved by our team of seasoned manufacturing engineers, who review CAD drawings, schematics and plans for viability, and to suggest possible cost saving methods or improvements.

Efficiency

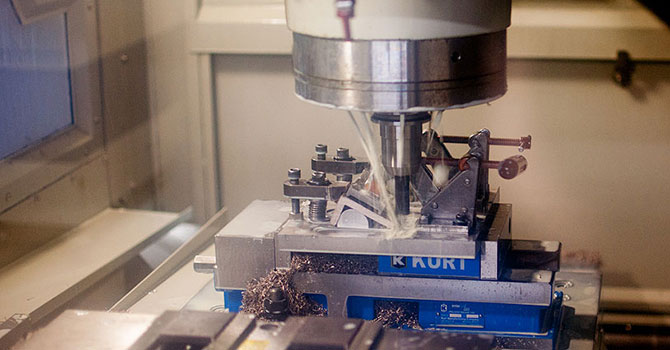

From sales order review to shipment, our state-of-the-art manufacturing facility is tuned for maximum efficiency. Incoming material storage, precision turning, precision milling, quality control, packaging and shipment areas are segregated and laid out in a thoughtful manner, ensuring that parts are manufactured quickly and to exacting specifications.

Experience

Our staff is made up of some of the area’s most experienced machinists and CNC operators. With more than 150 years of combined experience in the precision machining industry, there’s little they haven’t seen – and few problems they can’t foresee. That means potential machining challenges are often seen before they become issues, saving clients substantial amounts of frustration, time and money.

Technology

Gemini specializes in deploying state-of-the-art technology to both ease the ordering process and ensure the production of high-quality precision parts. Our capabilities include:

- A dedicated server for fax receipt, ensuring that data is saved and backed up – and that CNC programs are stored for future use

- Downloading and uploading of CNC programs via tablet, laptop or flash cards

- High-speed WiFi, to speed download and upload times and ensure fast turnarounds

- A color plotter, capable of printing up to full D-size drawing files, ensuring legible prints for the shop floor

- Access, viewing and importation of simple PDFs, 2D DXF and DWG drawing files to complex 3D STL and Solids

- CAM simulation tools, allowing us to review cutter paths, reducing scrap and increasing productivity

Our experienced team of precision machinists blends traditional techniques with cutting-edge technology, software and methodology to consistently produce quality parts at competitive rates.