At Gemini Machining, we specialize in dealing with extreme precision and demanding tolerances. That’s why we employ a dedicated quality control facility and staff, with the goal of delivering only perfect pieces to our clients.

Our precision machining quality control team has years of experience ensuring that clients’ needs are met, each and every time. Regardless of the job size, machining process or material, our standards for quality and continuous improvement are the highest in the industry. That’s why clients in fields like defense, aerospace, microwave and the life sciences have turned to Gemini Machining for decades.

Gemini Machining Quality Control Equipment

Our dedicated quality control facility includes:

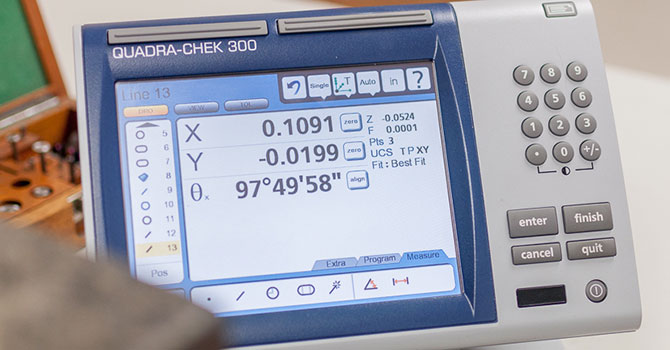

- Heidenhain Quadra-Chek QC330

- Brown & Sharpe MicroVal

- Brown & Sharpe Microhite Gauge

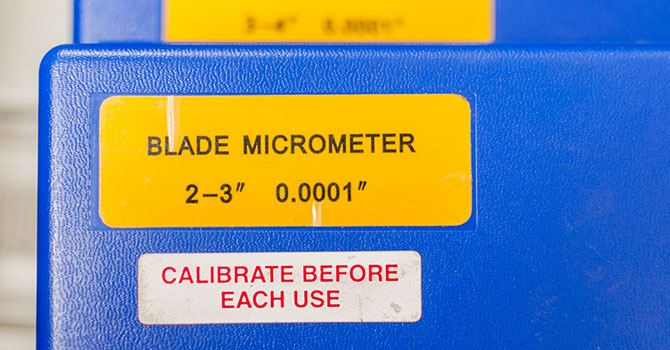

- Laser Micrometer

- Gage Master Optical Comparator

- Certified Granite Inspection Plates

- Certified Electronic Indicators

- Electronic Bore Gages

- Toolmakers Microscopes

- Thread Gages

- Pin Gages

Advanced Quality Control Practices

Gemini Machining is proud to offer our clients a full suite of advanced quality control services – far beyond what is offered in most precision machining facilities.

We are fully compliant with both industry and governmental standards, and ensure our clients’ compliance with statutes like ITAR, RoHS and Conflict Minerals reporting requirements. In addition, we employ a full-time, dedicated quality control inspector, whose only job is guaranteeing the accuracy and quality of jobs before they leave our doors.

We provide material certifications and C of C at no additional charge.

Geometrical Dimensioning & Tolerancing

Gemini Machining is proud to offer our clients a full suite of geometrical tolerancing and geometrical dimensioning services, fully compliant with the ASME Y14.5-2009 standard.

Our geometrical dimensioning and tolerancing specialists has years of experience helping clients avoid negative downstream effects by properly tolerancing plans. Our geometrical dimensioning and geometrical tolerancing services fundamentally improve the design and machining process, ensuring the viability and efficacy of plans before any expensive missteps take place. This improves both machining ROI and speed-to-market.